Application notes

Technical notes

Ask an engineer

Publications

United States (EN)

Select your region or country.

Emission Questions & Answers

- What are the main characteristics of xenon flash lamps?

- How does a deuterium-lamp-based VUV ionizer remove electrostatic charge in vacuum conditions?

- How does Hamamatsu measure the directivity of pulsed laser diodes (PLDs)?

- What is a “3-stack” PLD?

- Do you have any recommended driving conditions to achieve a longer life for packaged PLDs?

What are the main characteristics of xenon flash lamps?

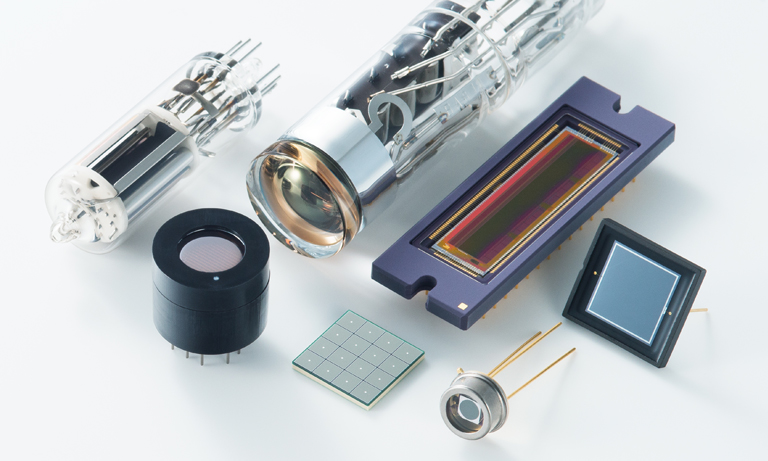

Xenon flash lamps are pulsed sources that emit a broad wavelength of light from 160 nm to approximately 7500 nm, so one light source (instead of multiple sources) can be used to generate light from UV to infrared. Their output intensity at UV wavelengths is especially high.

They also have advantages over continuous emission discharge lamps. For example, they don't require a long warm-up time, so they can be used right away after being turned on. Because they emit less heat than other types of lamps, they are ideal for designing and developing new instruments.

How does a deuterium-lamp-based VUV ionizer remove electrostatic charge in vacuum conditions?

A VUV ionizer contains a deuterium lamp that emits vacuum ultraviolet (VUV) light shorter than 200 nm, so the emission has high energy, about 10.78 eV. When absorbed, this high-energy light can ionize residual atoms and molecules in a vacuum condition. The ionized atoms or molecules are then attracted to charged surfaces, effectively neutralizing the charge.

In vacuum conditions, VUV light is more effective in removing electrostatic charge than x-rays because atoms and molecules have higher absorption coefficient for VUV than x-rays. Although x-rays have higher energy, they are more easily transmitted. So when there are fewer atoms and molecules available to ionize (such as in vacuum conditions), the absorption coefficient plays an important role.

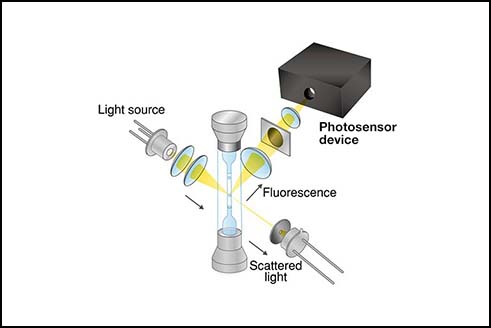

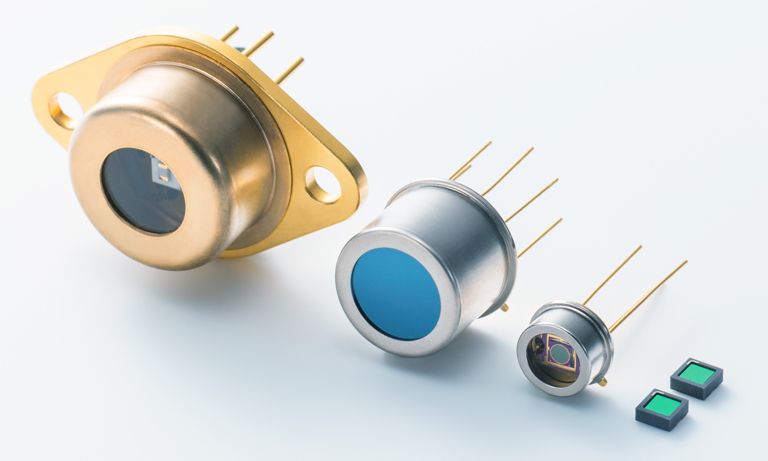

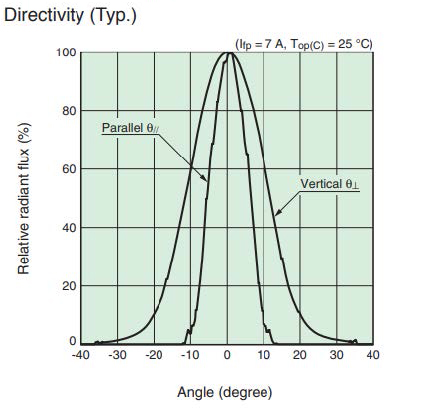

How does Hamamatsu measure the directivity of pulsed laser diodes (PLDs)?

A photodiode with a slit is scanned in an angular direction around the PLD to capture the relative intensity profile as a function of angle. The slit is set to a 1.0 deg. and 0.2 deg. resolution. See the figure below for an example directivity plot.

What is a “3-stack” PLD?

A 3-stack pulsed laser diode consists of three laser chips stacked on top of each other to make a single structure. It isn’t a single chip divided into three regions. We’ve found that having a stack of three chips results in optimal emission area efficiency.

Do you have any recommended driving conditions to achieve a longer life for packaged PLDs?

Failure modes for packaged PLDs can be caused by assembly distortion, solder migration, and crystal defects. These stressors are affected by the operating current, duty cycle, and operating temperature, so these operating conditions should be relaxed as much as possible to prolong the lifetime of the device.

If you have a technical question you’d like to see answered on this page, email us.

Meet the engineers

They say “a rolling stone gathers no moss.” But, Applications Engineer Masakazu “Moss” Kawazu decided to plant himself in the US for a few years and serve as our expert in light source and lamp futures. Originally from Japan, Kawazu is a big soccer fan and especially enjoyed all the exciting action of the World Cup this summer.

Mohamed is an Applications Engineer and optics expert, specializing in optical systems and lasers. He started reading and learning about the cosmos at a very early age, and that’s what drew him into studying physics and specializing in optics. When he’s not looking up at the sky wondering about the fabric of the universe, he can be found driving up and down mountain ranges chasing the most expansive vistas he can find.

- Confirmation

-

It looks like you're in the . If this is not your location, please select the correct region or country below.

You're headed to Hamamatsu Photonics website for US (English). If you want to view an other country's site, the optimized information will be provided by selecting options below.

In order to use this website comfortably, we use cookies. For cookie details please see our cookie policy.

- Cookie Policy

-

This website or its third-party tools use cookies, which are necessary to its functioning and required to achieve the purposes illustrated in this cookie policy. By closing the cookie warning banner, scrolling the page, clicking a link or continuing to browse otherwise, you agree to the use of cookies.

Hamamatsu uses cookies in order to enhance your experience on our website and ensure that our website functions.

You can visit this page at any time to learn more about cookies, get the most up to date information on how we use cookies and manage your cookie settings. We will not use cookies for any purpose other than the ones stated, but please note that we reserve the right to update our cookies.

1. What are cookies?

For modern websites to work according to visitor’s expectations, they need to collect certain basic information about visitors. To do this, a site will create small text files which are placed on visitor’s devices (computer or mobile) - these files are known as cookies when you access a website. Cookies are used in order to make websites function and work efficiently. Cookies are uniquely assigned to each visitor and can only be read by a web server in the domain that issued the cookie to the visitor. Cookies cannot be used to run programs or deliver viruses to a visitor’s device.

Cookies do various jobs which make the visitor’s experience of the internet much smoother and more interactive. For instance, cookies are used to remember the visitor’s preferences on sites they visit often, to remember language preference and to help navigate between pages more efficiently. Much, though not all, of the data collected is anonymous, though some of it is designed to detect browsing patterns and approximate geographical location to improve the visitor experience.

Certain type of cookies may require the data subject’s consent before storing them on the computer.

2. What are the different types of cookies?

This website uses two types of cookies:

- First party cookies. For our website, the first party cookies are controlled and maintained by Hamamatsu. No other parties have access to these cookies.

- Third party cookies. These cookies are implemented by organizations outside Hamamatsu. We do not have access to the data in these cookies, but we use these cookies to improve the overall website experience.

3. How do we use cookies?

This website uses cookies for following purposes:

- Certain cookies are necessary for our website to function. These are strictly necessary cookies and are required to enable website access, support navigation or provide relevant content. These cookies direct you to the correct region or country, and support security and ecommerce. Strictly necessary cookies also enforce your privacy preferences. Without these strictly necessary cookies, much of our website will not function.

- Analytics cookies are used to track website usage. This data enables us to improve our website usability, performance and website administration. In our analytics cookies, we do not store any personal identifying information.

- Functionality cookies. These are used to recognize you when you return to our website. This enables us to personalize our content for you, greet you by name and remember your preferences (for example, your choice of language or region).

- These cookies record your visit to our website, the pages you have visited and the links you have followed. We will use this information to make our website and the advertising displayed on it more relevant to your interests. We may also share this information with third parties for this purpose.

Cookies help us help you. Through the use of cookies, we learn what is important to our visitors and we develop and enhance website content and functionality to support your experience. Much of our website can be accessed if cookies are disabled, however certain website functions may not work. And, we believe your current and future visits will be enhanced if cookies are enabled.

4. Which cookies do we use?

There are two ways to manage cookie preferences.

- You can set your cookie preferences on your device or in your browser.

- You can set your cookie preferences at the website level.

If you don’t want to receive cookies, you can modify your browser so that it notifies you when cookies are sent to it or you can refuse cookies altogether. You can also delete cookies that have already been set.

If you wish to restrict or block web browser cookies which are set on your device then you can do this through your browser settings; the Help function within your browser should tell you how. Alternatively, you may wish to visit www.aboutcookies.org, which contains comprehensive information on how to do this on a wide variety of desktop browsers.

5. What are Internet tags and how do we use them with cookies?

Occasionally, we may use internet tags (also known as action tags, single-pixel GIFs, clear GIFs, invisible GIFs and 1-by-1 GIFs) at this site and may deploy these tags/cookies through a third-party advertising partner or a web analytical service partner which may be located and store the respective information (including your IP-address) in a foreign country. These tags/cookies are placed on both online advertisements that bring users to this site and on different pages of this site. We use this technology to measure the visitors' responses to our sites and the effectiveness of our advertising campaigns (including how many times a page is opened and which information is consulted) as well as to evaluate your use of this website. The third-party partner or the web analytical service partner may be able to collect data about visitors to our and other sites because of these internet tags/cookies, may compose reports regarding the website’s activity for us and may provide further services which are related to the use of the website and the internet. They may provide such information to other parties if there is a legal requirement that they do so, or if they hire the other parties to process information on their behalf.

If you would like more information about web tags and cookies associated with on-line advertising or to opt-out of third-party collection of this information, please visit the Network Advertising Initiative website http://www.networkadvertising.org.

6. Analytics and Advertisement Cookies

We use third-party cookies (such as Google Analytics) to track visitors on our website, to get reports about how visitors use the website and to inform, optimize and serve ads based on someone's past visits to our website.

You may opt-out of Google Analytics cookies by the websites provided by Google:

https://tools.google.com/dlpage/gaoptout?hl=en

As provided in this Privacy Policy (Article 5), you can learn more about opt-out cookies by the website provided by Network Advertising Initiative:

http://www.networkadvertising.org

We inform you that in such case you will not be able to wholly use all functions of our website.

Close