Application notes

Technical notes

Ask an engineer

Publications

United States (EN)

Select your region or country.

Mid-infrared Questions & Answers

How do I choose among an MIR LED, a QCL, and a xenon flash lamp?

There’s a famous phrase in the spectroscopy world, “fit for purpose.” This is a perfect mantra for selecting components. Selecting the right light source starts with the desired application. What are you trying to achieve with this instrument? What is the proper wavelength and power output? What market is it serving? What is the target final cost? The answers to those questions along with the explanations below should lead to an answer.

MIR LEDs

LEDs boast reliable lifetimes as well as low power consumption. They also come at a relatively low cost compared to other MIR light sources. The main tradeoff lies with power output, so these units are not intended for analytical accuracy. Portable gas monitors would be a great example application for these components.

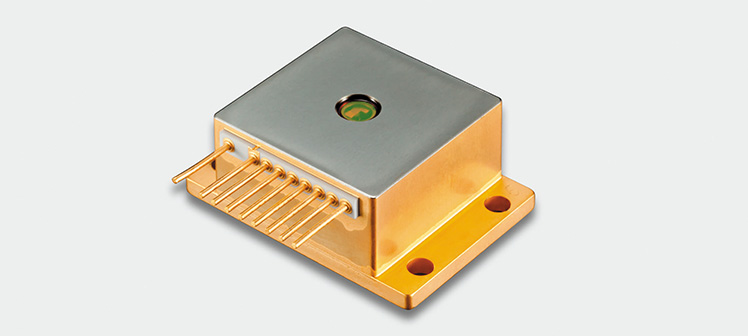

QCLs

Quantum cascade lasers (QCLs) are the gold standard for generating light anywhere between 4-10 microns. Our DFB (distributed feedback) models provide industry-leading linewidth resolution, enabling possible ppb measurements. QCLs also have reliable lifetimes while providing high power output. All this performance comes at a much higher cost, and power requirements for lasing start at around 500mA. An instrument using a QCL will be cost intensive and require quite a bit of expertise to pull off, but nothing will touch the sensitivity it can achieve.

Xenon (Xe) flash lamps

For wide spectral output and high frequency operation, look no further than the Xe flash lamp. With output ranging from 0.2 microns to 5+ microns, these lamps make it possible to create an instrument that detects multiple gases. However, these lamps should not be considered for measuring very low concentrations due to the wide output and stability. Although Xe flash lamps with emission out to 7 microns have been developed, the relative output past 5 microns remains low. Measurements further into the fingerprint region would be very difficult to achieve.

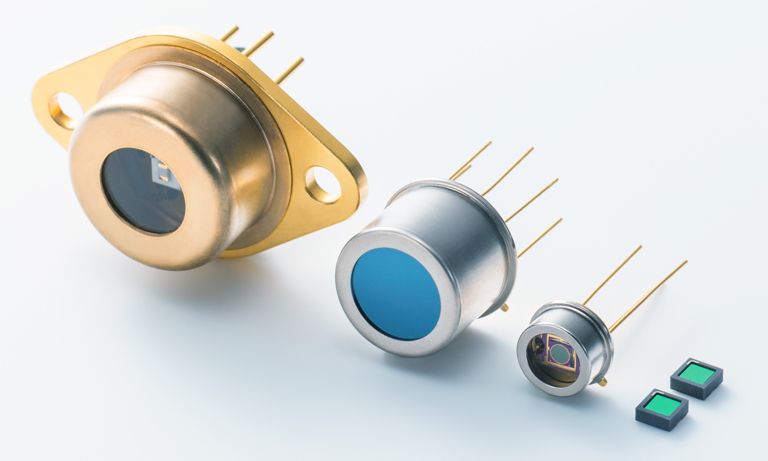

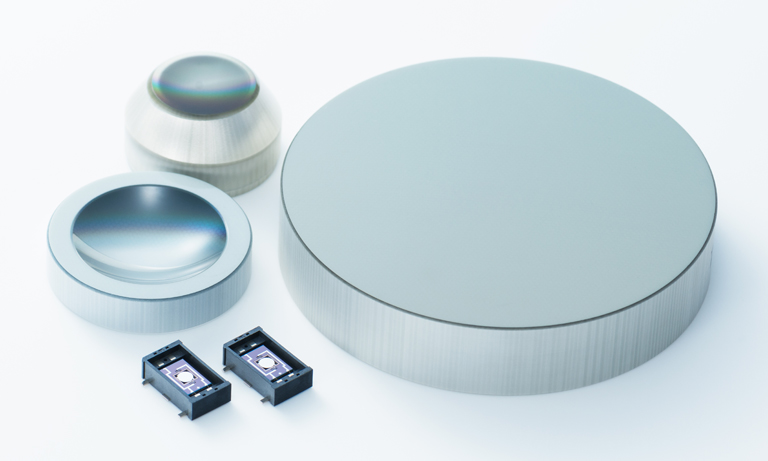

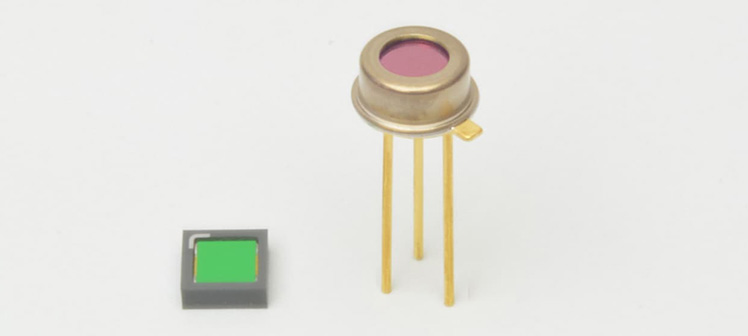

What is D* (D-star)?

D* is known as the “detectivity” of a detector, or the photosensitivity per unit active area in a detector. As seen in the equation below, the lower the noise equivalent power (NEP) of a detector, the higher the D* (and vice versa). NEP is the minimum power of signal needed for a detector to overcome its noise floor, or for SNR to equal 1. The lower this value, the higher the sensitivity of a detector. This relationship shows, therefore, that the higher the D*, the higher the sensitivity as well. We can also see from the equation below that the smaller the detector active area (A), the higher the D*.

D* takes into account more than just a detector’s active area, however. It is also a function of the temperature [K] or wavelength [µm] of a radiant source, the chopping frequency [Hz], and the bandwidth [Hz] of a detector—as seen in the expression of detectivity as “D* (A, B, C),” with each letter corresponding to the three characteristics mentioned.

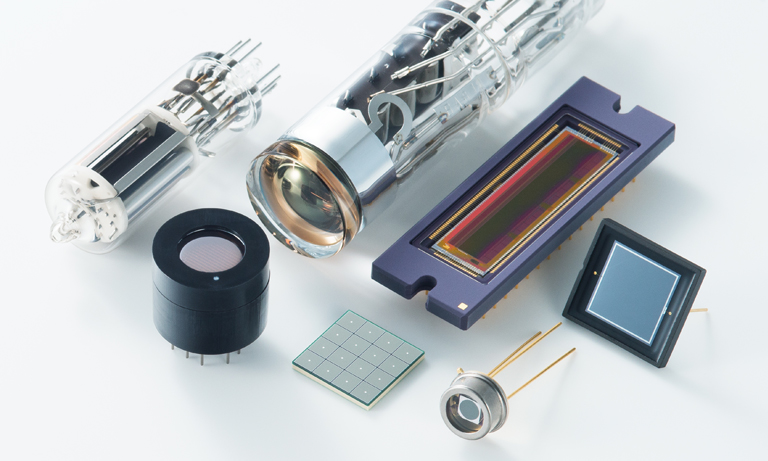

What makes D* so useful is that it allows a comparison of different active area sizes and chemistries. While D* provides a better gauge of sensitivity, detector characteristics such as light wavelength, response time, active area shape, and number of elements, as well as the necessary electronics, should be taken into account when selecting an infrared detector.

When the applications demand more sensitivity, cooling serves the function of lowering the noise floor of a detector without reducing its quantum efficiency (QE). As a result, the lower the temperature, the higher the D* at a certain input power. It’s important to remember that cooling drives up cost and complexity, so it’s best to consider uncooled detectors first. Hamamatsu offers a wide range of uncooled detectors as well as detectors with multi-stage thermoelectric (TEC) cooling and liquid nitrogen cooling.

Give me the short answer to “Why should I choose InAsSb?”

Photovoltaic operation typically leads to slower measurements. Hamamatsu’s InAsSb detectors mitigate that situation by boasting a rise time on the order of nanoseconds. In addition, many infrared detectors contain materials that are not RoHS compliant (mercury and lead), but InAsSb material is fully RoHS compliant. In uncooled applications, InAsSb is a strong contender for providing big cost advantages as well.

If you have a technical question you’d like to see answered on this page, email us.

Meet the engineers

Columbine Robinson is an applications engineer who grew up in lovely California. She’s always loved math and science, and received her Master’s Degree in Solid State Physics from UCSD. Prior to working at Hamamatsu Corporation, she was involved in semiconductor defect inspection where she gained vast experience in optics and image processing. Her hobbies include backpacking/hiking, playing chess, making pottery and cooking.

Gary Spingarn is a product manager in the New Jersey office of Hamamatsu, where he focuses on business development for certain products and exploring new applications. Leveraging his chemistry expertise, Gary supports the mid-infrared (MIR) product lines with a particular knack for process monitoring, gas analysis, and environmental applications. In his spare time, Gary hones his chess skills as well as partakes in strength sports and world travel.

- Confirmation

-

It looks like you're in the . If this is not your location, please select the correct region or country below.

You're headed to Hamamatsu Photonics website for US (English). If you want to view an other country's site, the optimized information will be provided by selecting options below.

In order to use this website comfortably, we use cookies. For cookie details please see our cookie policy.

- Cookie Policy

-

This website or its third-party tools use cookies, which are necessary to its functioning and required to achieve the purposes illustrated in this cookie policy. By closing the cookie warning banner, scrolling the page, clicking a link or continuing to browse otherwise, you agree to the use of cookies.

Hamamatsu uses cookies in order to enhance your experience on our website and ensure that our website functions.

You can visit this page at any time to learn more about cookies, get the most up to date information on how we use cookies and manage your cookie settings. We will not use cookies for any purpose other than the ones stated, but please note that we reserve the right to update our cookies.

1. What are cookies?

For modern websites to work according to visitor’s expectations, they need to collect certain basic information about visitors. To do this, a site will create small text files which are placed on visitor’s devices (computer or mobile) - these files are known as cookies when you access a website. Cookies are used in order to make websites function and work efficiently. Cookies are uniquely assigned to each visitor and can only be read by a web server in the domain that issued the cookie to the visitor. Cookies cannot be used to run programs or deliver viruses to a visitor’s device.

Cookies do various jobs which make the visitor’s experience of the internet much smoother and more interactive. For instance, cookies are used to remember the visitor’s preferences on sites they visit often, to remember language preference and to help navigate between pages more efficiently. Much, though not all, of the data collected is anonymous, though some of it is designed to detect browsing patterns and approximate geographical location to improve the visitor experience.

Certain type of cookies may require the data subject’s consent before storing them on the computer.

2. What are the different types of cookies?

This website uses two types of cookies:

- First party cookies. For our website, the first party cookies are controlled and maintained by Hamamatsu. No other parties have access to these cookies.

- Third party cookies. These cookies are implemented by organizations outside Hamamatsu. We do not have access to the data in these cookies, but we use these cookies to improve the overall website experience.

3. How do we use cookies?

This website uses cookies for following purposes:

- Certain cookies are necessary for our website to function. These are strictly necessary cookies and are required to enable website access, support navigation or provide relevant content. These cookies direct you to the correct region or country, and support security and ecommerce. Strictly necessary cookies also enforce your privacy preferences. Without these strictly necessary cookies, much of our website will not function.

- Analytics cookies are used to track website usage. This data enables us to improve our website usability, performance and website administration. In our analytics cookies, we do not store any personal identifying information.

- Functionality cookies. These are used to recognize you when you return to our website. This enables us to personalize our content for you, greet you by name and remember your preferences (for example, your choice of language or region).

- These cookies record your visit to our website, the pages you have visited and the links you have followed. We will use this information to make our website and the advertising displayed on it more relevant to your interests. We may also share this information with third parties for this purpose.

Cookies help us help you. Through the use of cookies, we learn what is important to our visitors and we develop and enhance website content and functionality to support your experience. Much of our website can be accessed if cookies are disabled, however certain website functions may not work. And, we believe your current and future visits will be enhanced if cookies are enabled.

4. Which cookies do we use?

There are two ways to manage cookie preferences.

- You can set your cookie preferences on your device or in your browser.

- You can set your cookie preferences at the website level.

If you don’t want to receive cookies, you can modify your browser so that it notifies you when cookies are sent to it or you can refuse cookies altogether. You can also delete cookies that have already been set.

If you wish to restrict or block web browser cookies which are set on your device then you can do this through your browser settings; the Help function within your browser should tell you how. Alternatively, you may wish to visit www.aboutcookies.org, which contains comprehensive information on how to do this on a wide variety of desktop browsers.

5. What are Internet tags and how do we use them with cookies?

Occasionally, we may use internet tags (also known as action tags, single-pixel GIFs, clear GIFs, invisible GIFs and 1-by-1 GIFs) at this site and may deploy these tags/cookies through a third-party advertising partner or a web analytical service partner which may be located and store the respective information (including your IP-address) in a foreign country. These tags/cookies are placed on both online advertisements that bring users to this site and on different pages of this site. We use this technology to measure the visitors' responses to our sites and the effectiveness of our advertising campaigns (including how many times a page is opened and which information is consulted) as well as to evaluate your use of this website. The third-party partner or the web analytical service partner may be able to collect data about visitors to our and other sites because of these internet tags/cookies, may compose reports regarding the website’s activity for us and may provide further services which are related to the use of the website and the internet. They may provide such information to other parties if there is a legal requirement that they do so, or if they hire the other parties to process information on their behalf.

If you would like more information about web tags and cookies associated with on-line advertising or to opt-out of third-party collection of this information, please visit the Network Advertising Initiative website http://www.networkadvertising.org.

6. Analytics and Advertisement Cookies

We use third-party cookies (such as Google Analytics) to track visitors on our website, to get reports about how visitors use the website and to inform, optimize and serve ads based on someone's past visits to our website.

You may opt-out of Google Analytics cookies by the websites provided by Google:

https://tools.google.com/dlpage/gaoptout?hl=en

As provided in this Privacy Policy (Article 5), you can learn more about opt-out cookies by the website provided by Network Advertising Initiative:

http://www.networkadvertising.org

We inform you that in such case you will not be able to wholly use all functions of our website.

Close