Application notes

Technical notes

Ask an engineer

Publications

United States (EN)

Select your region or country.

LiDAR Concepts Questions & Answers

- What types of LiDAR concepts are being worked on, and is there a LiDAR design that’s better than others in the market?

- If I were to design a LiDAR system, how do I know which type of photodetector is the right one?

- What are the possible light sources to use for my LiDAR concept?

- What do you think is the biggest challenge for a LiDAR system when going from prototype to production?

What types of LiDAR concepts are being worked on, and is there a LiDAR design that’s better than others in the market?

First, Hamamatsu does not make LiDAR systems; instead, we supply LiDAR companies with critical optical components or assemblies used in the LiDAR system. Because Hamamatsu is supporting many unique LiDAR designs, we have a general awareness of the types of LiDAR concepts in the market today and those being discussed for the future.

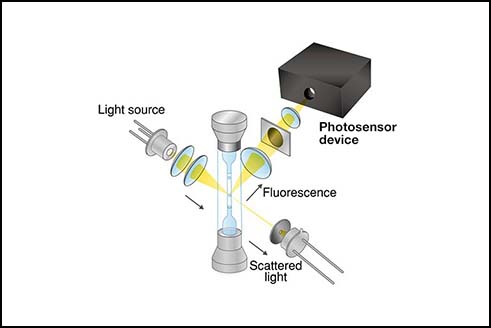

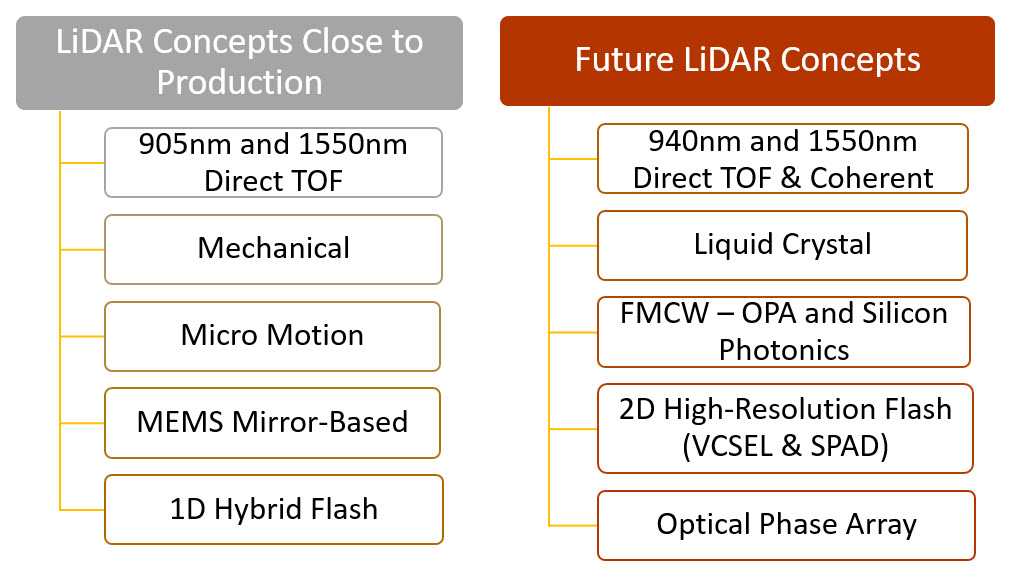

As of spring 2021, I think many 905nm and 1550nm direct TOF (time of flight) concepts are proven and headed toward production, while long-range, high-resolution flash LiDAR or coherent LiDAR concepts like FMCW (frequency-modulated continuous wave) are being touted as future LiDAR concepts (see Fig. 1).

Also, I feel each LiDAR concept has its own benefits that make it best-suited for a specific use case, such as for ADAS, autonomous vehicles, robots, industrial automation, security, or other markets/applications. Therefore, I don’t believe there’s one concept that’s better than others.

Figure 1. Examples of LiDAR concepts

If I were to design a LiDAR system, how do I know which type of photodetector is the right one?

Well, this is a complex question to answer, and it really depends on the system-level requirements.

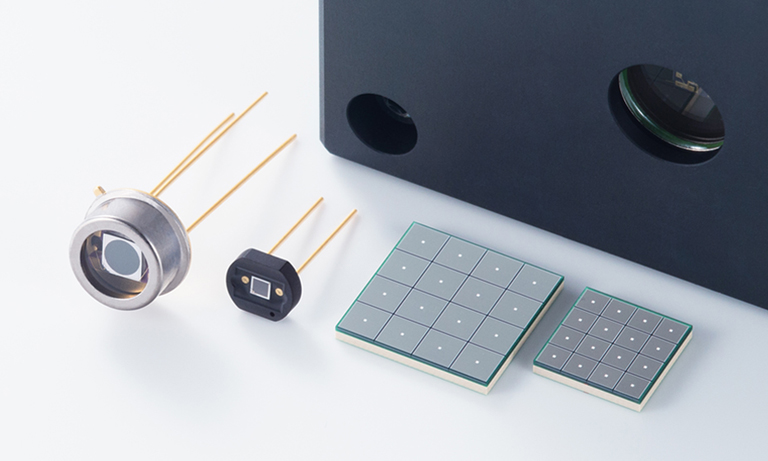

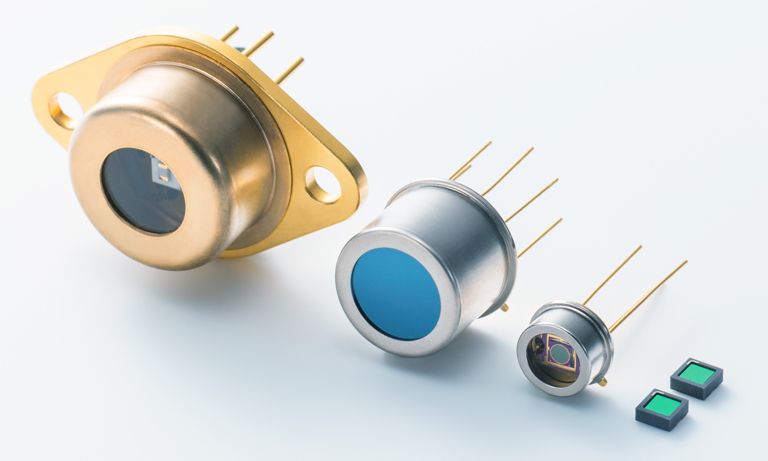

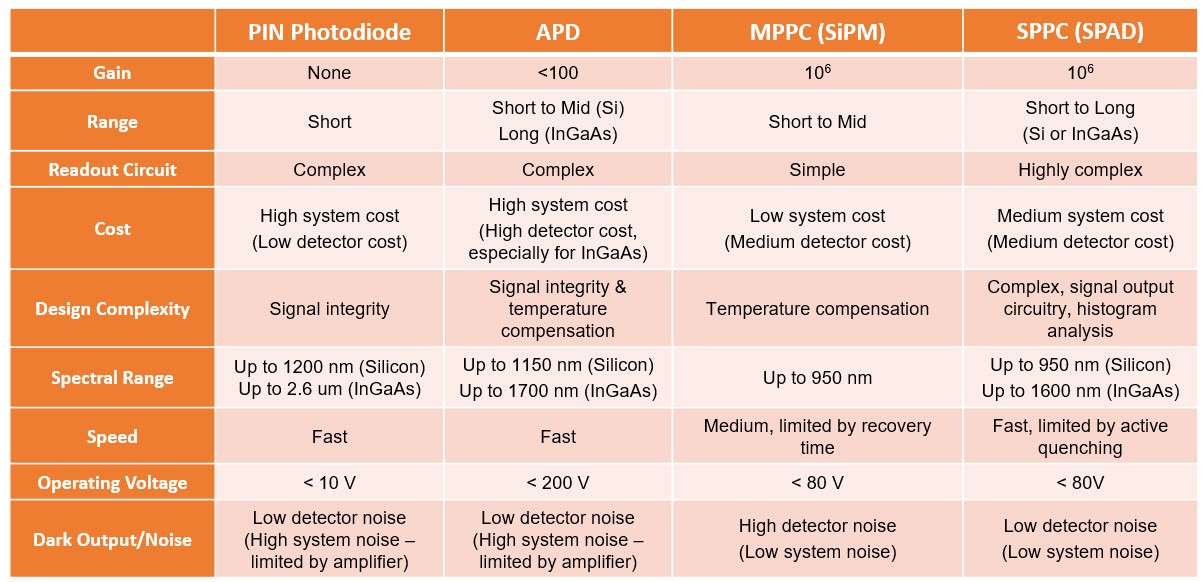

Generally, there are 4 types of detector technologies:

- PIN diode

- Avalanche photodiode (APD)

- Silicon photomultiplier (SiPM) or MPPC (Multi-Pixel Photon Counter)

- Single-photon avalanche diode (SPAD) or SPPC (Single-Pixel Photon Counter)

They can be offered either with silicon materials for the 850-940nm LiDAR concepts or InGaAs materials for the 1550nm LiDAR concepts. Each of these detector technologies is unique and has benefits suitable for different LiDAR concepts. See Table 1 below to get an idea of how the detectors are different from each other.

I would also suggest talking to Hamamatsu directly about the type of LiDAR design you are trying to make and the system-level requirements, so we can walk you through the different parameters of detectors, such as sensitivity, recovery time, dynamic range, noise, and more, to help you make the optimal choice.

Because Hamamatsu has all 4 photodetector technologies, we aren’t biased and wouldn’t attempt to sway you toward any one of these photodetectors. We understand the time to market is critical for a LiDAR company’s success, so we don’t want to steer you toward the wrong path that would be difficult to return from.

Visit our main website to see our photodetector technologies.

Table 1: Comparison of photodetector technologies for LiDAR systems

What are the possible light sources to use for my LiDAR concept?

There are various light sources to consider depending on the LiDAR design, but generally, edge-emitting lasers or VCSELs are being considered for 850-940nm LiDAR concepts, and fiber lasers or DFB (distributed feedback) lasers for direct TOF or FMCW 1550nm LiDAR concepts.

When considering the right sources for 850-940nm LiDAR concepts, the edge-emitting lasers are good choices for a scanning type of LiDAR, and VCSELs are best for flash LiDAR concepts. Then for 1550nm, high-power fiber lasers or other types of high-power lasers are great for TOF LiDAR concepts, while FMCW LiDAR requires lasers with lower power but narrow linewidth.

The considerations for which laser product is best can be complex, depending on the various system-level requirements such as range, resolution, range error, and reliability. You must also consider light source factors such as NFP (near field pattern), peak power output, laser efficiency, linewidth, stability, and others.

The best way to pick the right laser is to let Hamamatsu know your system-level requirements, so we may provide recommendations for the best source.

What do you think is the biggest challenge for a LiDAR system when going from prototype to production?

There are several challenges that LiDAR startups or designers should consider even at the prototype stage, so they are prepared when the concept is ready for production.

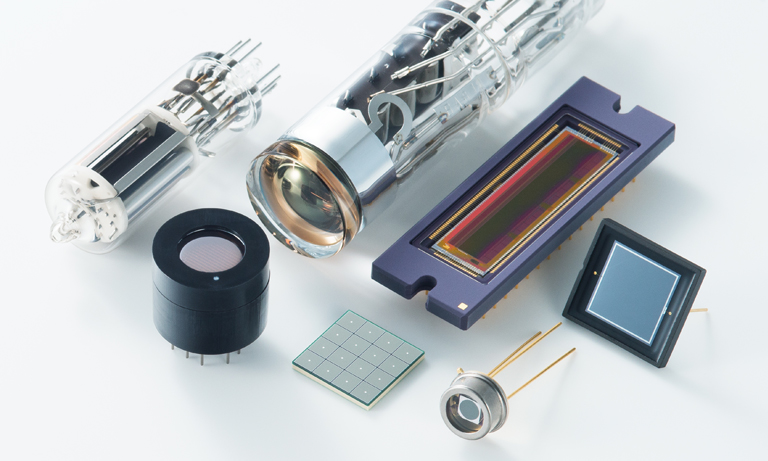

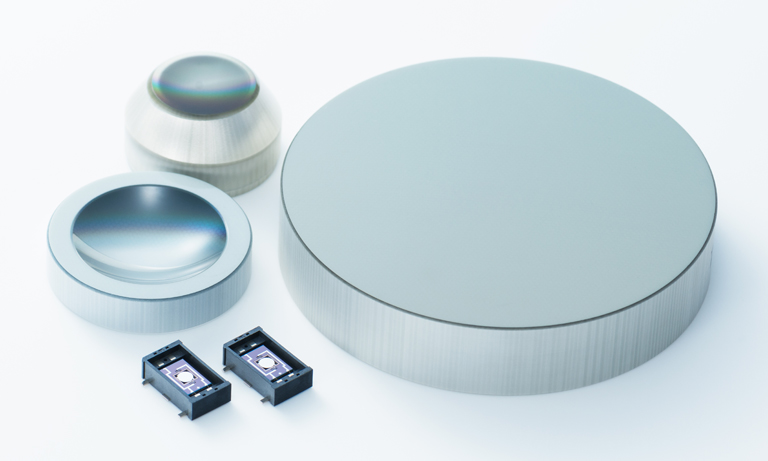

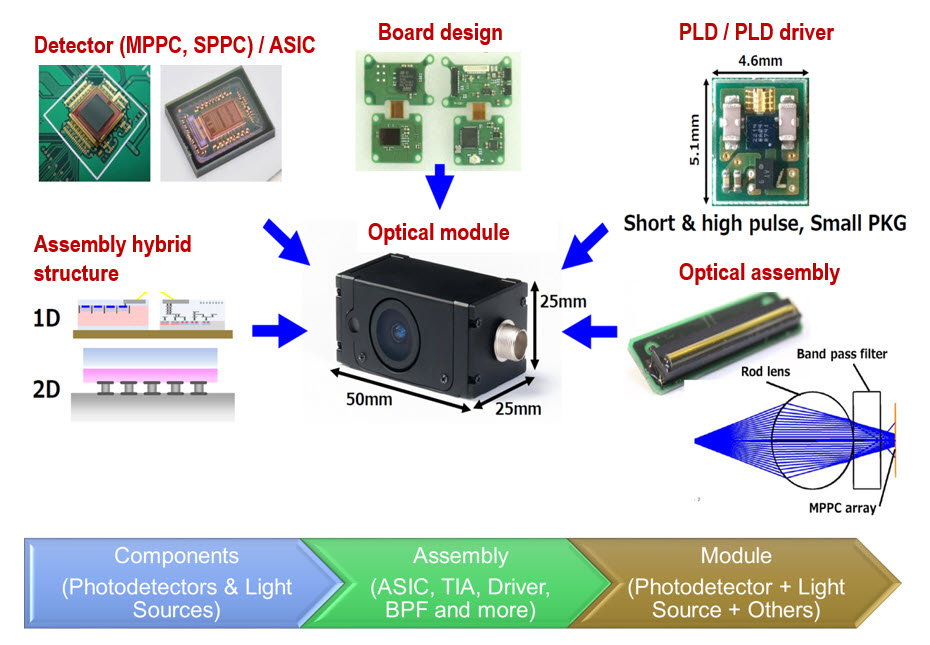

For example, one of the main challenges is meeting the qualification and reliability requirements for an automotive-grade LiDAR system. Certain AEC and ISO standards are a must when the system is approved to be used in the harsh automotive environment. The various standards and qualifications create many headaches since most LiDAR concepts at the prototype stage are built with discrete components, which means complex supplier management as well as qualification needs. This is why more and more LiDAR system makers are moving toward more integrated assembly type of solutions. Fig. 2 below showcases Hamamatsu’s solutions—from discrete components to assemblies to modules—that are suitable depending on if the LiDAR system is at the prototype or production stage.

Another key challenge is the need for customization. LiDAR designs are different from each other, so the light sources, detectors, and assemblies will have different requirements from one LiDAR concept to the next. This poses challenges to suppliers, such as Hamamatsu, to be able to take on multiple customization requests from customers that want different detector, source, or assembly designs. The customizations could be as simple as changing the gap size between detector elements in an array, or as complex as adding new functions into an ASIC design or modifying the complete optical assembly that includes sources and detectors. Fortunately, Hamamatsu can provide simple to complex customization since more than 80% of our sales is based on custom designs.

Of course, there are more challenges than just the two I mentioned, and I’d love to talk to you more about this topic. Please contact us to further discuss these challenges or your customization needs.

Figure 2. Hamamatsu offers discrete components, assemblies, and modules for LiDAR systems. Customization available.

If you have a technical question you’d like to see answered on this page, email us.

Meet the engineer

Jake Li is a Business Development Manager at Hamamatsu, working in the New Jersey office. He has been with Hamamatsu for 7 years and focuses on business development opportunities related to new Hamamatsu products such as silicon photomultiplier (or MPPC) and single-photon avalanche diode (or SPPC), as well as emerging markets such as LiDAR (light detection and ranging) for automotive, industrial automation, robotics, and other fields. He enjoys playing golf, snowboarding in the winter, and taking on new personal or professional challenges.

- Confirmation

-

It looks like you're in the . If this is not your location, please select the correct region or country below.

You're headed to Hamamatsu Photonics website for US (English). If you want to view an other country's site, the optimized information will be provided by selecting options below.

In order to use this website comfortably, we use cookies. For cookie details please see our cookie policy.

- Cookie Policy

-

This website or its third-party tools use cookies, which are necessary to its functioning and required to achieve the purposes illustrated in this cookie policy. By closing the cookie warning banner, scrolling the page, clicking a link or continuing to browse otherwise, you agree to the use of cookies.

Hamamatsu uses cookies in order to enhance your experience on our website and ensure that our website functions.

You can visit this page at any time to learn more about cookies, get the most up to date information on how we use cookies and manage your cookie settings. We will not use cookies for any purpose other than the ones stated, but please note that we reserve the right to update our cookies.

1. What are cookies?

For modern websites to work according to visitor’s expectations, they need to collect certain basic information about visitors. To do this, a site will create small text files which are placed on visitor’s devices (computer or mobile) - these files are known as cookies when you access a website. Cookies are used in order to make websites function and work efficiently. Cookies are uniquely assigned to each visitor and can only be read by a web server in the domain that issued the cookie to the visitor. Cookies cannot be used to run programs or deliver viruses to a visitor’s device.

Cookies do various jobs which make the visitor’s experience of the internet much smoother and more interactive. For instance, cookies are used to remember the visitor’s preferences on sites they visit often, to remember language preference and to help navigate between pages more efficiently. Much, though not all, of the data collected is anonymous, though some of it is designed to detect browsing patterns and approximate geographical location to improve the visitor experience.

Certain type of cookies may require the data subject’s consent before storing them on the computer.

2. What are the different types of cookies?

This website uses two types of cookies:

- First party cookies. For our website, the first party cookies are controlled and maintained by Hamamatsu. No other parties have access to these cookies.

- Third party cookies. These cookies are implemented by organizations outside Hamamatsu. We do not have access to the data in these cookies, but we use these cookies to improve the overall website experience.

3. How do we use cookies?

This website uses cookies for following purposes:

- Certain cookies are necessary for our website to function. These are strictly necessary cookies and are required to enable website access, support navigation or provide relevant content. These cookies direct you to the correct region or country, and support security and ecommerce. Strictly necessary cookies also enforce your privacy preferences. Without these strictly necessary cookies, much of our website will not function.

- Analytics cookies are used to track website usage. This data enables us to improve our website usability, performance and website administration. In our analytics cookies, we do not store any personal identifying information.

- Functionality cookies. These are used to recognize you when you return to our website. This enables us to personalize our content for you, greet you by name and remember your preferences (for example, your choice of language or region).

- These cookies record your visit to our website, the pages you have visited and the links you have followed. We will use this information to make our website and the advertising displayed on it more relevant to your interests. We may also share this information with third parties for this purpose.

Cookies help us help you. Through the use of cookies, we learn what is important to our visitors and we develop and enhance website content and functionality to support your experience. Much of our website can be accessed if cookies are disabled, however certain website functions may not work. And, we believe your current and future visits will be enhanced if cookies are enabled.

4. Which cookies do we use?

There are two ways to manage cookie preferences.

- You can set your cookie preferences on your device or in your browser.

- You can set your cookie preferences at the website level.

If you don’t want to receive cookies, you can modify your browser so that it notifies you when cookies are sent to it or you can refuse cookies altogether. You can also delete cookies that have already been set.

If you wish to restrict or block web browser cookies which are set on your device then you can do this through your browser settings; the Help function within your browser should tell you how. Alternatively, you may wish to visit www.aboutcookies.org, which contains comprehensive information on how to do this on a wide variety of desktop browsers.

5. What are Internet tags and how do we use them with cookies?

Occasionally, we may use internet tags (also known as action tags, single-pixel GIFs, clear GIFs, invisible GIFs and 1-by-1 GIFs) at this site and may deploy these tags/cookies through a third-party advertising partner or a web analytical service partner which may be located and store the respective information (including your IP-address) in a foreign country. These tags/cookies are placed on both online advertisements that bring users to this site and on different pages of this site. We use this technology to measure the visitors' responses to our sites and the effectiveness of our advertising campaigns (including how many times a page is opened and which information is consulted) as well as to evaluate your use of this website. The third-party partner or the web analytical service partner may be able to collect data about visitors to our and other sites because of these internet tags/cookies, may compose reports regarding the website’s activity for us and may provide further services which are related to the use of the website and the internet. They may provide such information to other parties if there is a legal requirement that they do so, or if they hire the other parties to process information on their behalf.

If you would like more information about web tags and cookies associated with on-line advertising or to opt-out of third-party collection of this information, please visit the Network Advertising Initiative website http://www.networkadvertising.org.

6. Analytics and Advertisement Cookies

We use third-party cookies (such as Google Analytics) to track visitors on our website, to get reports about how visitors use the website and to inform, optimize and serve ads based on someone's past visits to our website.

You may opt-out of Google Analytics cookies by the websites provided by Google:

https://tools.google.com/dlpage/gaoptout?hl=en

As provided in this Privacy Policy (Article 5), you can learn more about opt-out cookies by the website provided by Network Advertising Initiative:

http://www.networkadvertising.org

We inform you that in such case you will not be able to wholly use all functions of our website.

Close